Optimization of cast parts

In the automobile industry, the use of optimization tools is standard in all sections of construction and development. The number of pieces in the automobile industry and the wind industry differs but the amount of casted material in the wind industry is increasing. There is a growing potential for weight optimization, especially regarding cast parts of the drive train. With the help of modern computer based design methods, this potential can be shown and used in an optimal way.

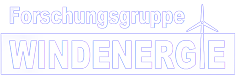

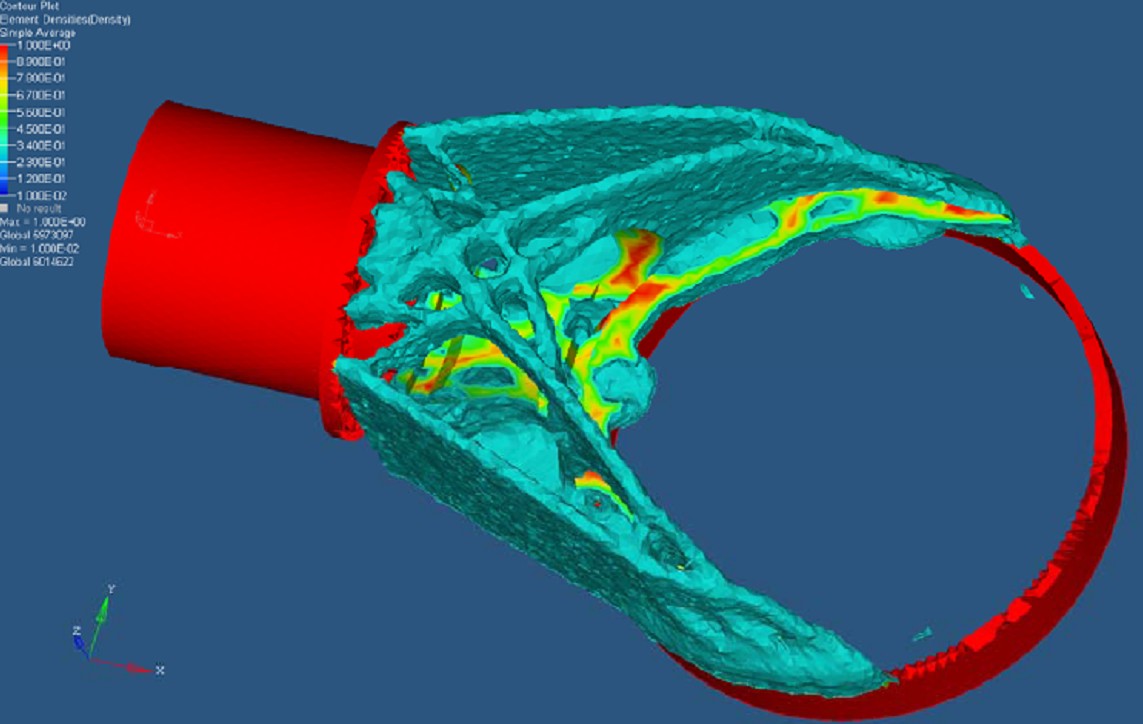

In the automobile industry, the use of optimization tools is standard in all sections of construction and development. The number of pieces in the automobile industry and the wind industry differs but the amount of casted material in the wind industry is increasing. There is a growing potential for weight optimization, especially regarding cast parts of the drive train. With the help of modern computer based design methods, this potential can be shown and used in an optimal way.Therefore, INNOWIND uses weight optimization software based

on finite element analysis. With this software, individual load cases as well as load collectives as a function of time can be considered in the calculation. Furthermore, the software offers the possibility to consider limitations as well as boundary and secondary conditions for the castability, mechanical processing and mounting during optimization. With this software, minimum wall thicknesses and draw directions can be predefined and so an optimal cast part design without undercuts in draw direction can be generated.

on finite element analysis. With this software, individual load cases as well as load collectives as a function of time can be considered in the calculation. Furthermore, the software offers the possibility to consider limitations as well as boundary and secondary conditions for the castability, mechanical processing and mounting during optimization. With this software, minimum wall thicknesses and draw directions can be predefined and so an optimal cast part design without undercuts in draw direction can be generated.